- Overview

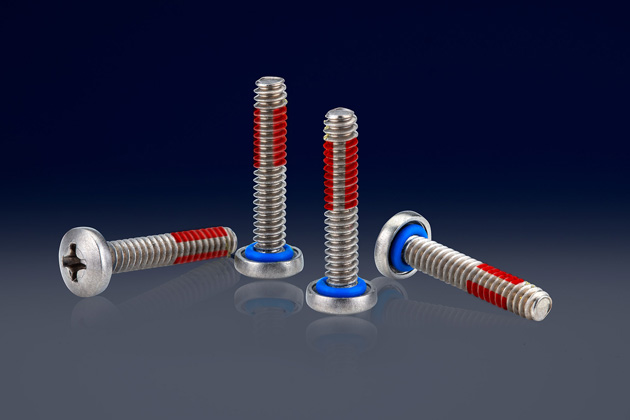

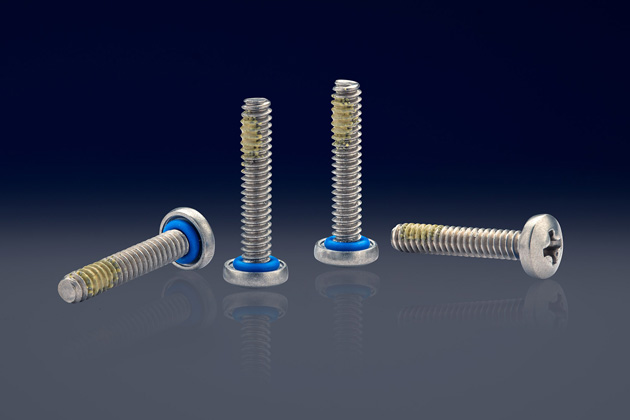

- What are Sealing Fasteners?

- What are Security Screws?

- Clearance Hole Data

- Dimensional Tables

- Installation and Torque

- Pro-Tips for Choosing Screw Material

- Choosing Your O-Ring Material

- Sealing Screws Engineering

- Crystal Switch Seals Specifications

- Self-Sealing Nuts Engineering

- Switch Boots Engineering

- Product Catalog (PDF)